A cartoning machine or cartoner, is a packaging machine that forms cartons: erect, close, folded, side seamed, and sealed cartons.

Packaging machines form a carton board blank into a carton filled with a product or bag of products or number of products say into a single carton, after the filling, the machine engages its tabs/slots to apply adhesive and close both the ends of the carton completely sealing the carton.

Cartoning machines can be divided into two types:

A cartoning machine that picks a single piece from a stack of folded cartons and erects it, fills it with a product or bag of products or number of products horizontally through an open end, and closes by tucking the end flaps of the carton or applying glue or adhesive. The product might be pushed in the carton either through the mechanical sleeve or by pressurized air. For many applications, however, the products are inserted into the carton manually. This type of Cartoning machine is widely used for packaging foodstuffs, confectionery, medicine, cosmetics, sundry goods, etc.

A cartoning machine that erects a folded carton, fills with a product or number of products vertically through an open end, and closes by either tucking the end flaps of the carton or applying glue or adhesive, is called an end-load cartoning machine.[6] Cartoning machines are widely used for packaging bottled foodstuffs, confectionery, medicine, cosmetics, etc., and can vary based on the scale of the business.

Horizontal Cartoning Machine

Vertical Cartoning Machine

About Folding Carton

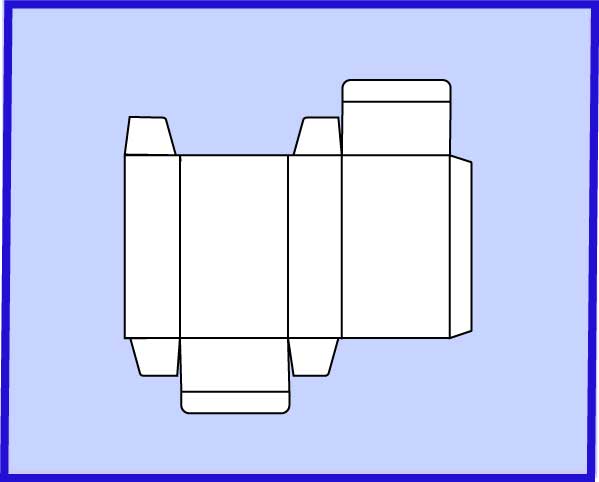

The folding carton created the packaging industry as it is known today, beginning in the late 19th century. The process involves folding cartons made of paperboard that is printed, laminated, cut, then folded and glued. The cartons are shipped flat to a packager, which has its own machinery to fold the carton into its final shape as a container for a product.

Folding cartons are now a $110 billion industry. Typically, a cylinder board made from pulp from reprocessed scrap paper is used for most packages. Cartons for food are made from a higher grade and lighter solid sulfate board with a plastic coating. Because of the limitations of cutting machinery, the thickness of the board is limited to 0.81 mm (0.032 in), and folding cartons are generally limited to holding a few pounds or kilograms of material.

Opening a carton can be accomplished by opening an access flap, cutting, use of tear tapes or perforations.