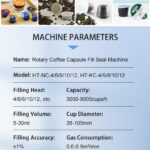

Coffee capsule filling sealing machine is a multifunctional high-speed automatic machine specially designed for coffee products (or other kinds of powder products, such as tea powder, cocoa powder, etc. ) to be filled and sealed. This coffee capsule sealing machine is specially designed for cups with rolled film or pre-cut lid products (or other kinds of liquid products, such as fruit juice, water, and even granules and powder and others, etc. ) to be filled and sealed. This coffee cup-filling machine can automatically make plastic cups, and other cups according to customers’ demand.

Coffee Capsule Filling Sealing Machine is specially designed for coffee cups filled and sealed. The machine is a multi-functional high-speed full automatic machine for different sizes of cups according to clients’ requirements. The machine is applied with world-famous electrical and pneumatic components.

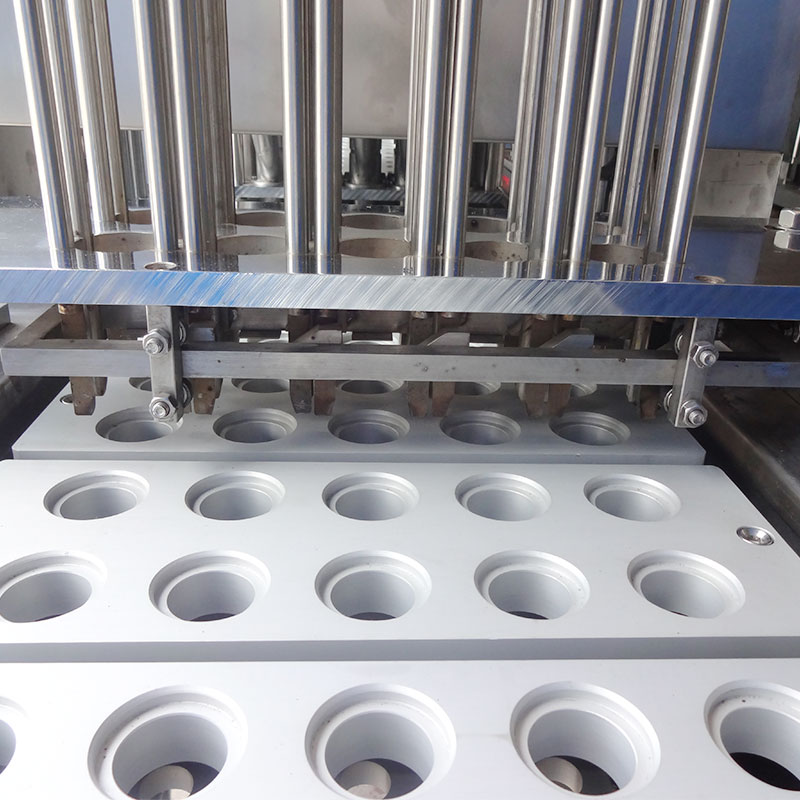

This series of filling and sealing machines is our patent machine specially designed to produce coffee capsule cups. The machine can fill coffee powder (or other tea powder, cocoa powder) into cups, put the plastic filter layer on top of the powder, remove redundant coffee out of the cups, hot sealing, punching(cutting) by full automatically. It can be avoided cups secondary pollution. Machine control by PLC and adopt servo motor driving system, all the electrical parts adopt famous brand, such as snider, Mitsubishi, Omron, etc. This machine can be also connected to a coffee capsule box packing machine.

Applications:

- Filling Materials: various granules, powder, and liquid materials. Such as coffee, milk powder, tea, instantly soluble powder, yogurt, and other food materials.

- Packing Container: Plastic Coffee Capsules, Aluminum Coffee Capsules, Small Cups, etc.

Features

- Stable, reliable, safe, with alarm function.

- Variable frequency control, the filling time can be adjustable.

- The configuration elements adopt the international famous brand.

- High filling accuracy, suitable for all kinds of cups.

- Alarm and shut down when the gas supply is low.

- Easy to clean and maintain.

Process

- Falling Capsules: Capsules drop down one by one automatically.

- Tank Mixing: Mixing coffee powder.

- Filling Coffee: Powder auger filling type.

- Press Coffee: Press coffee tight.

- Sucking Putting Foils: Vacuum arm suck and put foils.

- First Sealing: 0-300 degrees, can be adjusted.

- Second Sealing: 0-300 degrees, can be adjusted.

- Push-Out Finished Capsules: Push-out finished capsules to a platform.

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net