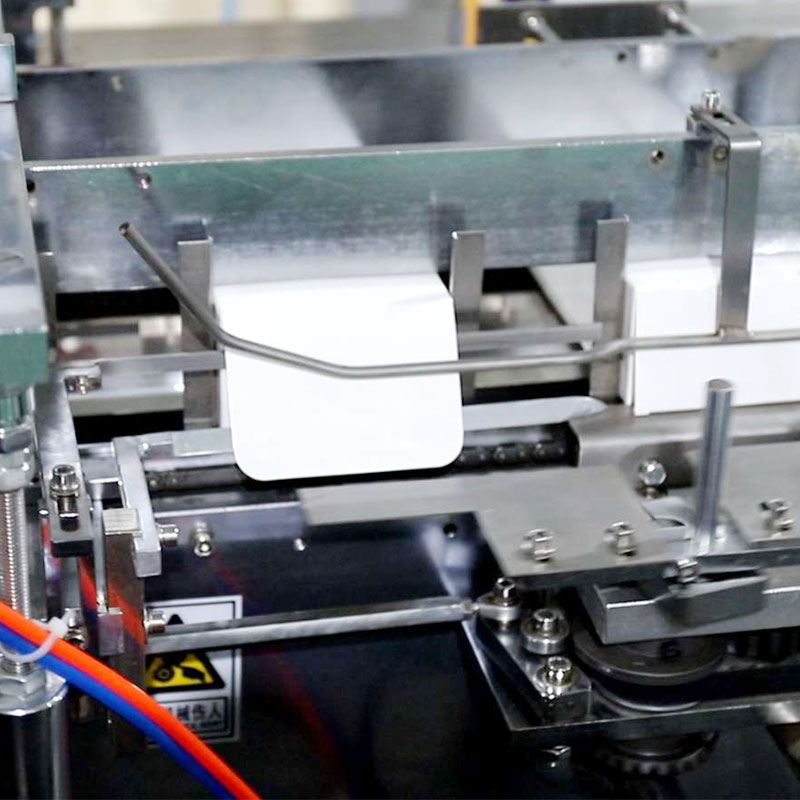

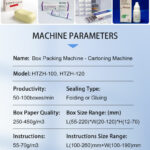

- Folding manual paper and sending it into the box, feeding, opening the box, pushing into the box, marking batch number, sealing the box, and removing waste automatically. Compact and reasonable structure, easy to operate and adjust.

- Using a servo/stepper motor and touch screen, PLC makes the man-machine interface display clear, operation more simple, with a higher degree of automation, and more human.

- Automatic photoelectric detection and tracking system is adopted to save packaging materials to the greatest extent.

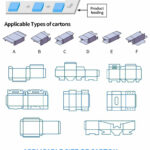

- The packaging range is large and easy to adjust, and a variety of specifications can be quickly converted between sizes.

- It is not necessary to replace the mold to replace the specification, only adjustment can be achieved.

- The use of items in the box is not in place automatic stop box and the main drive motor overload protection device, are safer and more reliable.

- According to customer requirements, the use of an upturned safety cover, is easy to operate, a beautiful appearance.

- It can realize joint production with an aluminum-plastic packaging machine, pillow packaging machine, 3d packaging machine, bottling line, filling machine, labeling machine, code spraying machine, online weighing machine, and other production line lighting equipment.

- According to the packaging, requirements can design a variety of automatic feeding devices and box systems.

- A hot melt glue machine can be selected according to the customer’s requirements, which adopts hot melt glue spraying to seal the box and a mechanical brush to seal the box.

- Full intelligent touch screen, microcomputer control of the packaging process, easy-to-understand operation of the control of mechanical equipment and production process, reliability, and operation speed.

- It’s used 304 and 316 stainless steel bodies with higher durability.

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net