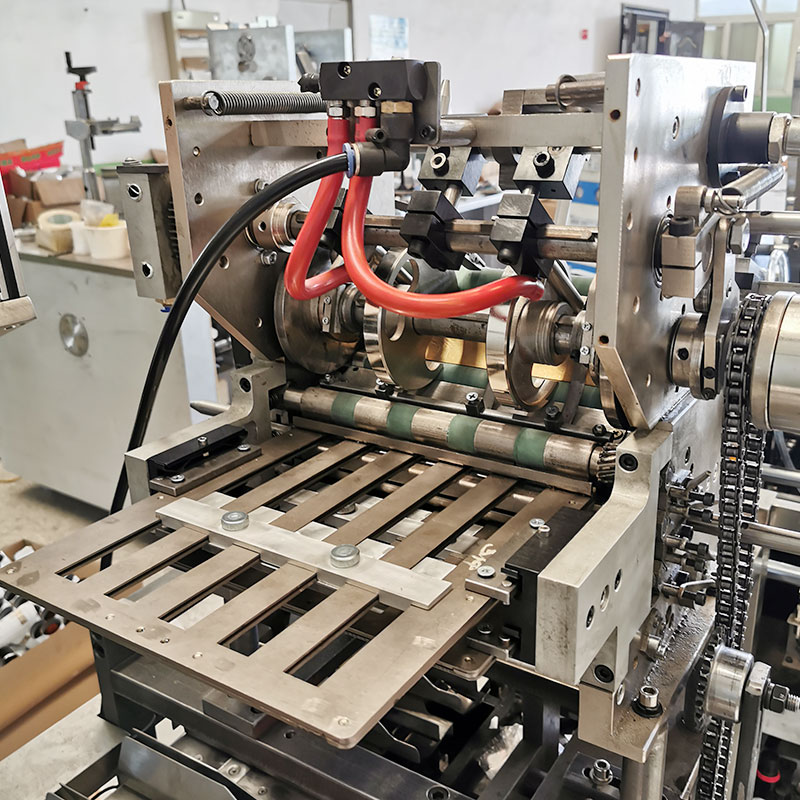

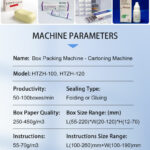

HTZH-120 box packing machine suitable for pharmaceuticals, medical, food, cosmetics, household chemicals, hardware, and electrical industries for the packaging of blisters, bottles, vials, pillow packs, toothpaste, etc. The machine is widely used in the pharmaceutical, food, cosmetic, and healthcare industries. It can fold leaflets, open cartons, insert the products and leaflets into cartons, emboss, tuck-in, or hot-melt closures and automatically discharge cartons.

The box-packing machine – cartoning machine is equipped with a series of sensors and automatic protective devices to assure the machine runs safely and effectively. It can connect with a tube filling sealing machine, pillow packaging machine, shrink-wrapper, etc., to form a packaging line. It is the best choice for mass production.

Box packing machine is a packaging machine that can put the products into the carton automatically: open, load, close, and seal cartons. Cartoning machines are widely used for packaging bottled foodstuffs, confectionery, medicine, cosmetics, etc., and can vary based on the scale of business- stainless steel machine body design, PLC control system.

It can run continuously and is suitable for the high-speed automatic packing of small packages. It includes the functions of carton erecting, leaflet folding, product inserting, carton sealing, and batch printing. The equipment has a high accuracy of transmission and excellent stability at high speed.

Features

- Folding manual paper and sending it into the box, feeding, opening the box, pushing into the box, marking batch number, sealing the box, and removing waste automatically. Compact and reasonable structure, easy to operate and adjust.

- Using a servo/stepper motor and touch screen, PLC makes the man-machine interface display clear, operation more simple, with a higher degree of automation, and more human.

- Automatic photoelectric detection and tracking system is adopted to save packaging materials to the greatest extent.

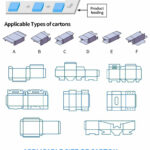

- The packaging range is large and easy to adjust, and a variety of specifications can be quickly converted between sizes.

- It is not necessary to replace the mold to replace the specification, only adjustment can be achieved.

- The use of items in the box is not in place automatic stop box and the main drive motor overload protection device, are safer and more reliable.

- According to customer requirements, the use of an upturned safety cover, is easy to operate, a beautiful appearance.

- It can realize joint production with aluminum-plastic packaging machines, pillow packaging machines, 3d packaging machines, bottling lines, filling machines, labeling machines, code spraying machines, online weighing machines, and other production line lighting equipment.

- According to the packaging, requirements can design a variety of automatic feeding devices and box systems.

- A hot melt glue machine can be selected according to the customer’s requirements, which adopts hot melt glue spraying to seal the box and a mechanical brush to seal the box.

- Full intelligent touch screen, microcomputer control of the packaging process, easy-to-understand operation of the control of mechanical equipment and production process, reliability, and operation speed.

- It’s used 304 and 316 stainless steel bodies with higher durability.

Optional Features

- Auto Conveyor (connect our machine with your present machine to be a whole automatic line).

- Hot Melt Glue (can be American Nordson, Domestic, Spain Meler, Switzerland Robotech).

- Other brands like Siemens (inverter, PLC, touch screen).

- Print the batch number or date on the carton box.

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net