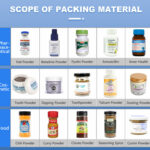

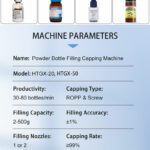

A powder bottle or jar filling machine is one kind of application of auger filler or auger dosing machine. It is suitable to fill 5 grams to 5000 grams of any powder in rigid containers including plastic bottles, glass bottles, metal tin cans, jars, tubs, buckets, boxes, drums, and pails.

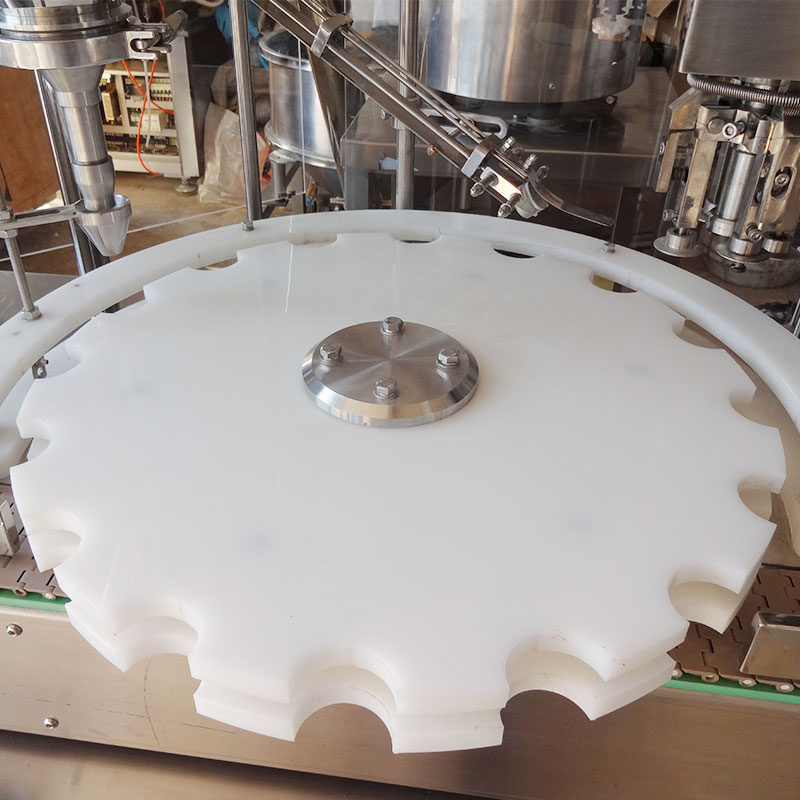

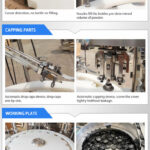

The machine’s indexing sub-plate positioning of the upper plug lower cover is provided by the high-precision cam indexing mechanism. It has the advantages of precise positioning, smooth transmission, protection of bottle caps, accurate measurement, and simple operation. Fully comply with national GMP requirements.

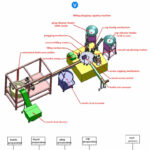

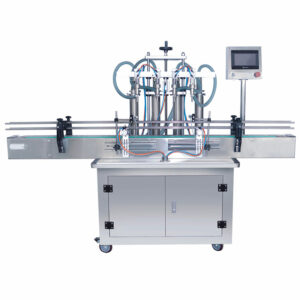

Powder filling capping machine mainly consists of filling components, stainless steel barrel, and other mechanisms. The appearance of filling capping machine is made of 304 stainless steel, resistant to corrosion. Comply with national GMP design requirements. Stable performance, high filling accuracy. Not easy to leak. Easy to remove and replace the screw. Strong connection stability with automatic production line, high filling efficiency! Through the replacement of screws, accessories can adapt to a variety of bottle specifications and powder particles of material packaging.

This machine is even more user-friendly. The whole machine has the advantage of reasonable structure, good appearance, stable running status, easy operation, and convenient disassembling and cleaning. It fully complies with GMP.

Features

- Computer control, loading volume accurate, easy to operate.

- Host speed can be stepless frequency control.

- Production of automatic quantitative control.

- Multiple faults prompt.

- Automatic stop function, automatic shutdown in the presence of continuous and no filling.

- Easy to maintain with SUS304 stainless steel exterior.

- 316L stainless steel screw filling, very strong corrosion resistance.

- This equipment complies with GMP requirements.

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net