Biaozan’s Tube Filler Sealer Machines have a high degree of automation, automatic loading, automatic color matching, automatic sealing, batch numbering, and automatic discharging. Using the internal heating method, the Swiss “LEISTER” hot air heater is used to blow hot air from the inner wall of the hose, thereby melting the plastic, and then marking and batch number. The indexing adopts a precision cam indexing mechanism, and the positioning is accurate and stable. The main motor adopts frequency conversion speed regulation, users can adjust the running speed by themselves.

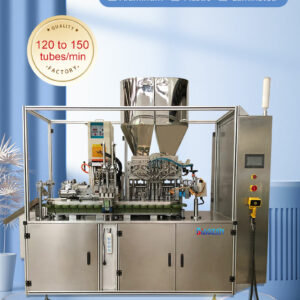

Our tube filler sealer machine fills products in cylindrical or oval metal, laminate and plastic tubes. Biaozan’s tube filler machine capacities ranging from 25 to 150 tubes/minute are available with different models like Linear tube filling machines, and rotary tube filling machines to meet today’s tube packaging demands in different industries.