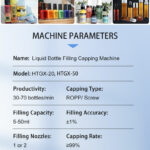

Small bottle filling capping machine is applicable for essential oil, eyedrops, e-liquid, vial, spray, chubby gorilla, tincture dropper bottles, glass dropper bottles, syrup, nail polish bottles, etc. The machine is designed according to the products and sample bottles and caps, there can be with or without plugs.

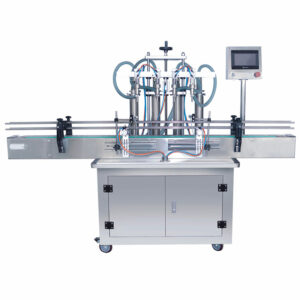

The bottle filling and capping machine is perfectly suited for handling cosmetics, OTC pharmaceuticals, and other liquid products. The Bellow Bottle Machine is a bottle-filling and automatic capping system designed for packaging liquids in plastic or glass containers with caps. Its cost-effective operating costs, diverse functionality, and impressive efficiency make our featured bottle-filling and capping machine a one-of-a-kind packaging solution.

- Adopt a human-computer interface, the PLC controller is easy to operate.

- Use frequency converting control, easy to adjust the filling speed, automatic count.

- Automatic stop, no bottle no filling.

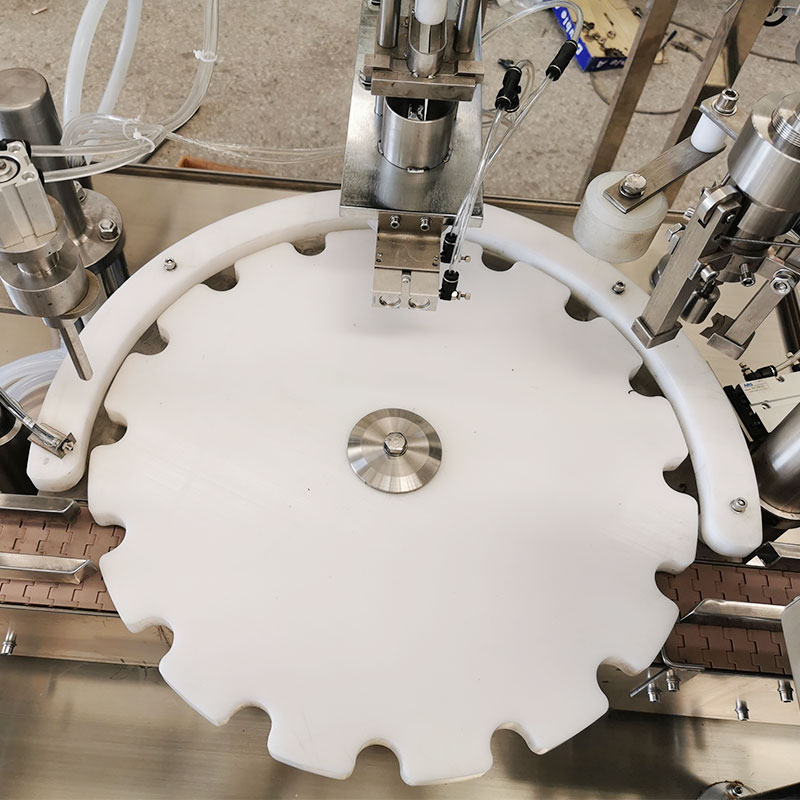

- Round turntable for positioning filling, stable, and reliable.

- High-precision CAM indexing gauge control.

- Filling: Via a conveyor belt to carry the bottom of the bottle to the filling head and the bottle was blocked by the dial to step forward, this time-synchronous filling heads into the bottom of the bottle and completed filling by a quantitative piston pump.

- Put Cover: Caps vibrate through an electromagnetic oscillator, so cover up the delivery chute, through the bottle fell to the track, and then was pressed by the press head.

- Capping: Filling finished bottle-fed by a conveyor belt on the turntable, the turntable through the sheave box for intermittent operation. When a bottle with a cap carries to the bottle caper housing for intermittent pauses, the capping head will be pressed lower by a cam and rotate clockwise, thus boosting the cap tightened.

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net