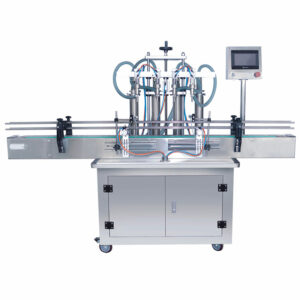

Rotary capping machine is a big help to mass production; it automates capping bottles and jars faster than an assembly line of human hands at any given time. Their precision and rate of production are unmatched, giving bottlers and other factories the edge in meeting demands on time.

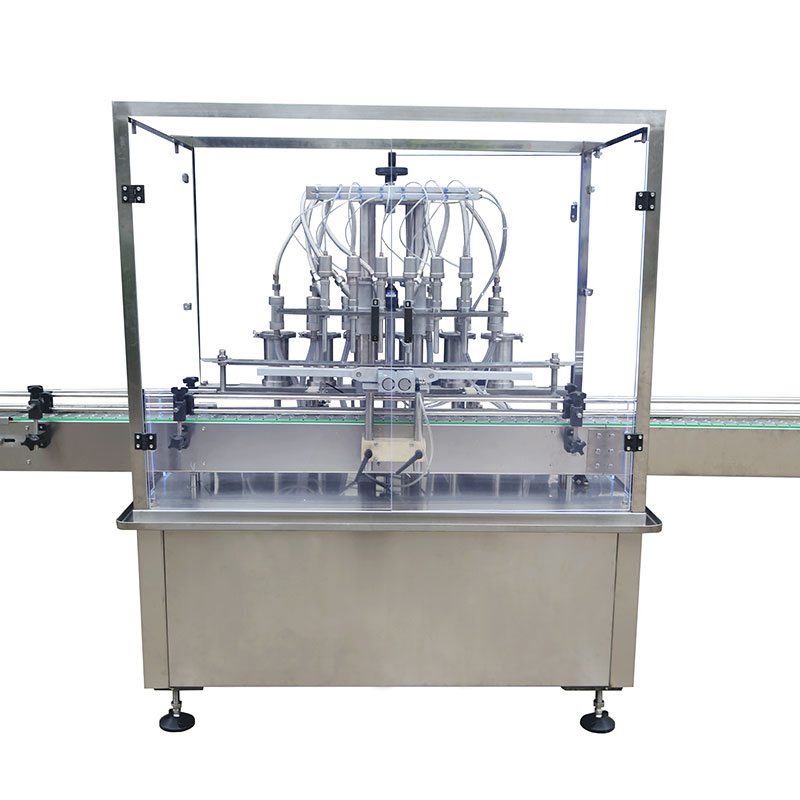

The placement of the sealing cap is carefully controlled to enhance safety and functionality. Photosensors are incorporated to ensure that sealing cannot proceed without an aluminum cap in the chute or stopper on the bottle. The device uses spring-loaded sealing rollers which do not damage the cap. The sealing machine is compact, and easy to install and operate. The speed can be adjusted to achieve varying production.

Rotary capping machine is integral to every packaging system. Bottle cappers help make sure that containers are consistently and properly sealed and ready to move on to the next step in the packaging process. Capping is often one of the last steps preceding selling to distributors or delivering to customers.

We produce a variety of automatic capping machines for different applications and production speeds, and for all sorts of bottle corks: We supply Automatic Capping Machines for crown corks, plastic caps and sports caps, Aluminium ROPP caps, Pre-threaded caps, Natural corks, Champagne type corks, T shape corks, Press on closures, Guala type closures and Twist off closures.

Shanghai Biaozan is among the leading manufacturers of capping machines in use in many factories today. For more than 17 years, we’ve brought quality workmanship in our capping machines and their accessories to great effect. There are many reasons why bottlers and other industries prefer our cappers.

Features

- Capping, capping, and capping are done by one machine.

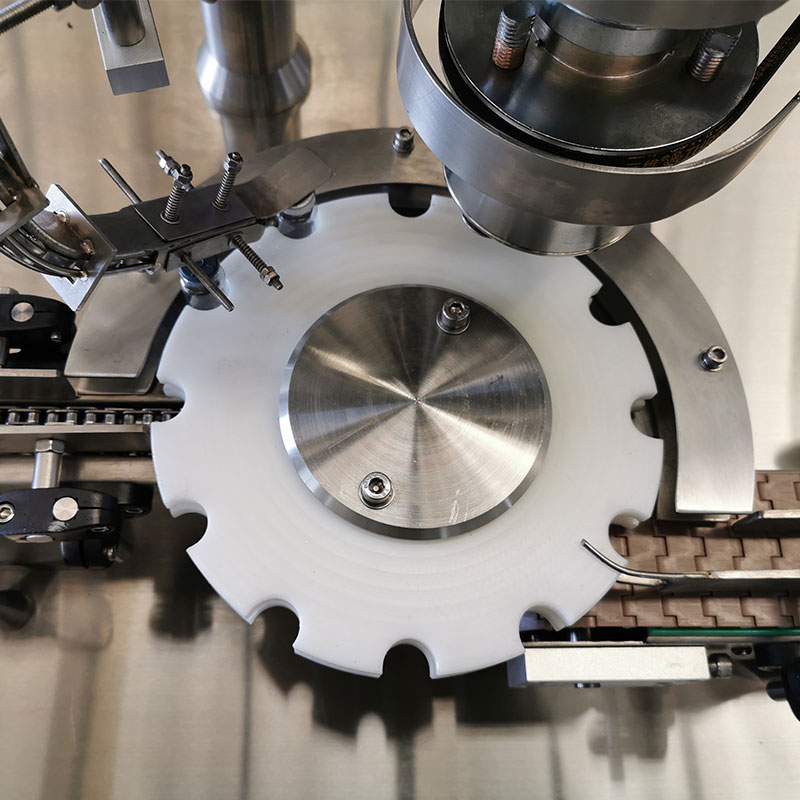

- Three-knife rotary capping method, beautiful, stable, and good sealing.

- The bottle-feeding tray is dragged by an independent motor and can be adjusted steplessly to prevent the bottle from falling down when the speed is too fast.

- When there are insufficient bottles or inverted bottles on the bottle feeding track, the machine can automatically stop to prevent bottle jams.

- A large number of stainless steel materials and anti-leakage treatments are used, which comply with GMP standards.

- The countertop components are installed with high columns, with a beautiful appearance and easy cleaning and wiping.

- At the same time, the factory’s exclusive anti-falling bottle device uses a photoelectric sensor to detect when a horizontal bottle enters the bottle inlet, it can automatically protect and stop the machine. Can save users a lot of raw material funds, while minimizing damage to the machine, which can extend the life of the machine.

Leave your contact information to get a quotation!