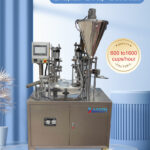

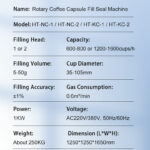

Our coffee capsule filling sealing machine adopts an Italian design concept, its range of versatile and flexible machines is equipped for filling & sealing capsules on a rotary table or multi-lane, integrates automatic sorting, filling nitrogen gas flushing, and sealing in a single block, it’s possible to adapt different types of the compatible capsule with various shapes and sizes, such as K- Cup, Nespresso, Dolce Gusto, Lavazza, etc. Filled with coffee, tea, barley, infusions, or soluble products and sealed with heat-sealing material.

The rotary coffee capsule filling and sealing machine is the latest design, fully mechanized-driven; we use cams and rods to make each station’s operation smoother, more precise, and more stable. The coffee capsule filling machine is a fully automatic machine and very popular because of its small size, fast speed, and ease to use. We have built this machine to produce aluminum capsules and plastic capsules.

This is a customized-built machine, you can use your own designed capsules in this machine. It is suitable for packaging a wide range of liquid, paste, granulated and powdered products, you can use this machine to fill dairy products, soluble powders, coffee, salads, dressings, desserts, dry soups, frozen dishes, cosmetics, nespresso capsule filler and so on. This coffee capsule filling sealing machine can also connect with the coffee capsule box packing machine.

Applications

- Filling Materials: various granules, powder, and liquid materials. Such as coffee, milk powder, tea, instantly soluble powder, yogurt, and other food materials.

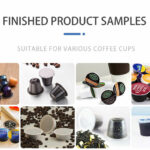

- Packing Container: Plastic Capsules, Aluminum Capsules, Small Cups, etc.

Features

- Stable, reliable, safe, with alarm function.

- Variable frequency control, the filling time can be adjustable.

- The configuration elements adopt the international famous brand.

- High filling accuracy, suitable for all kinds of cups.

- Alarm and shut down when the gas supply is low.

- Easy to clean and maintain.

Process

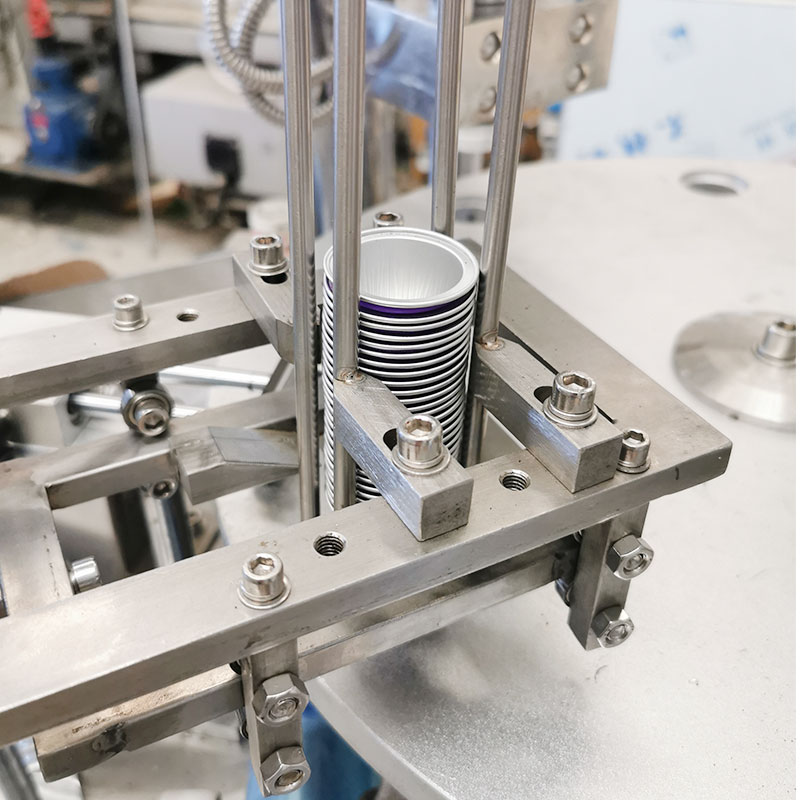

- Falling Coffee Capsules: Capsules drop down one by one automatically.

- Tank Mixing: Mixing coffee powder.

- Filling Coffee: powder Auger filling type.

- Press Coffee: Press coffee tight.

- Sucking Putting Foils: Vacuum arm suck and put foils.

- Sealing: 0-300 degrees, can be adjusted.

- Push-Out Finished Capsules: Push-out finished cups to a platform.

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net