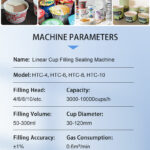

Linear cup filling machine is designed for filling liquid and pasty products in plastic cups from 100 to 500 ml. with sealing by pre-cut aluminum foil lid or by film from the roll. Also, pick and place the closure of the plastic overlap.

This machine is a fully automatic, in-line filling and sealing machine that is based on digital, mechanical, and pneumatic assemblies. This automatic packing machine is suitable for packaging a wide range of liquid, paste, granulated, and powdered products into preformed containers of various sizes and shapes. The machine can be used for dairy products, salads, dressings, desserts, dry soups, frozen dishes, cosmetics, and much more.

Linear cup filling machine made in Japan dragoness programmable logic controller, pneumatic control components, intelligent digital display temperature control system, sealed with high strength, good sealing, low failure rate, cover an area of an area small, etc, is the first choice for enterprise automation production products.

- Adopt a human-computer interface, the PLC controller, easy to operate.

- Use frequency converting control, easy to adjust the filling speed, automatic count.

- Automatic stop, no cup no filling.

- Round turntable for positioning filling, stable, and reliable.

- High-precision CAM indexing gauge control.

Process

- Falling Cups: Cups drop down one by one automatically.

- Filling Materials: All parts are directly in contact with a product made of SUS-304.

- Sucking Putting Foils: Vacuum arm suck and put foils.

- Press Plastic Cover: Press the plastic cover tightly.

- First Sealing: 0-300 degrees, can be adjusted.

- Second Sealing: 0-300 degrees, can be adjusted.

- Push-Out Finished Cups: Push-out finished cups to a platform.

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net