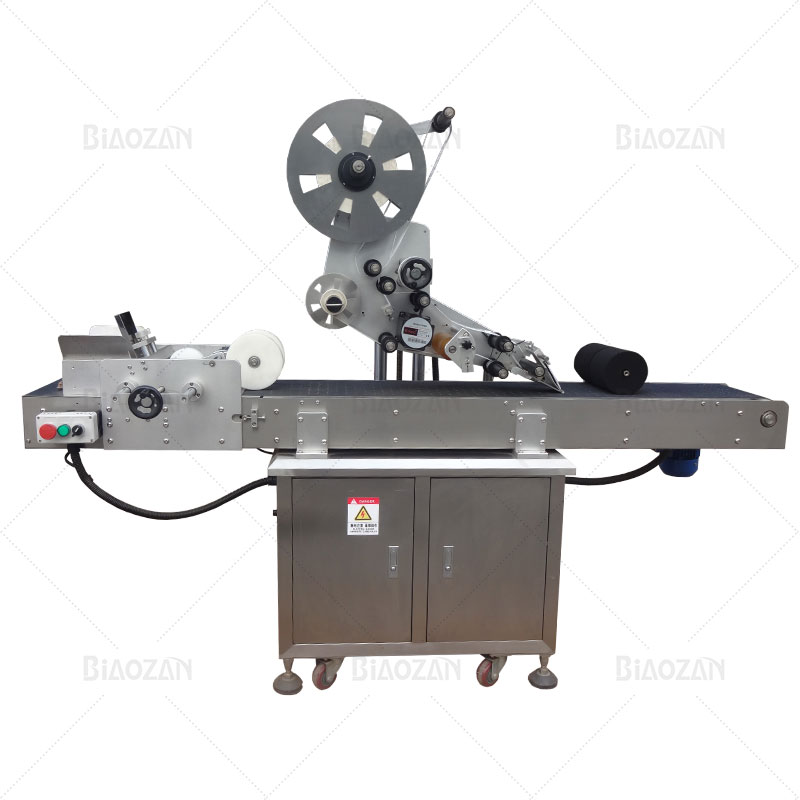

Flat labeling machine is used in top surface labeling of various packaging objects, like a lid, cap, box, cartons, and many more, which is used in a wide range of industries such as pharmaceuticals, cosmetics, chemical, food, beverage, pesticides, gifts, agriculture, electronics, etc.

Micro-computer control system. Super-large touch screen, easy to operate. Adopts servo motors, speed time to improve the accuracy of labeling parameters memory for fast-for-like production. The entire machine for the high-level stainless steel and aluminum alloy by anointing composition, never rust, in line with the GMP standard.

Flat labeling machine synchronized to maintain the high precision and the stability by microcomputers, softly labeling and subtly adjusting the labels to be adhesive smoothly with no wrinkles. We provide user-friendly operative automatic labeling machines for the factories of the food, the chemical engineering, the pharmacy, the technology, the cosmetics, and the machinery. Many kinds of types of machines are available, such as wraparound labelers, top&bottom labelers, two-side automatic labelers, automatic labelers, three-side labelers, side-adhesion roll-fed labelers, tamp labelers and print&apply labelers, memory card labelers, bar-code labelers, etc. As a whole-plant equipment factory of food, pharmacy, and technology, Biaozan has rich and extensive experience for our clients.

Flat labeling machine is suitable for labeling a wide range of products. One machine can basically achieve all the requirements of flat product labeling, especially for low-volume, variety, and changeable specifications labeling which can largely improve the labeling production efficiency and reduce equipment investment costs.

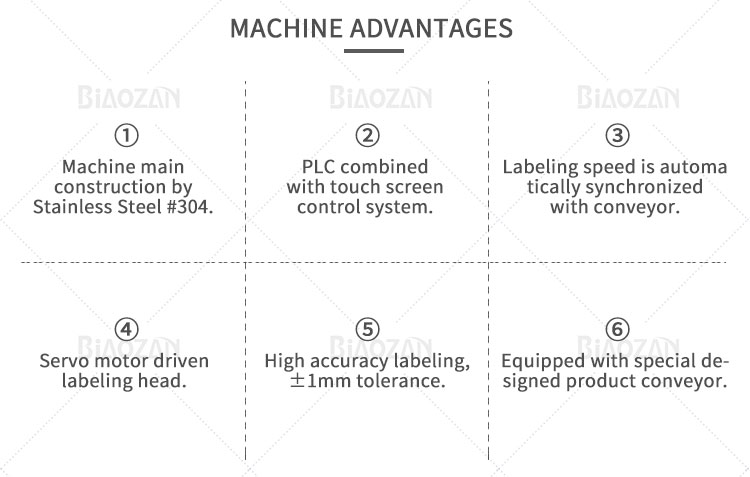

Features

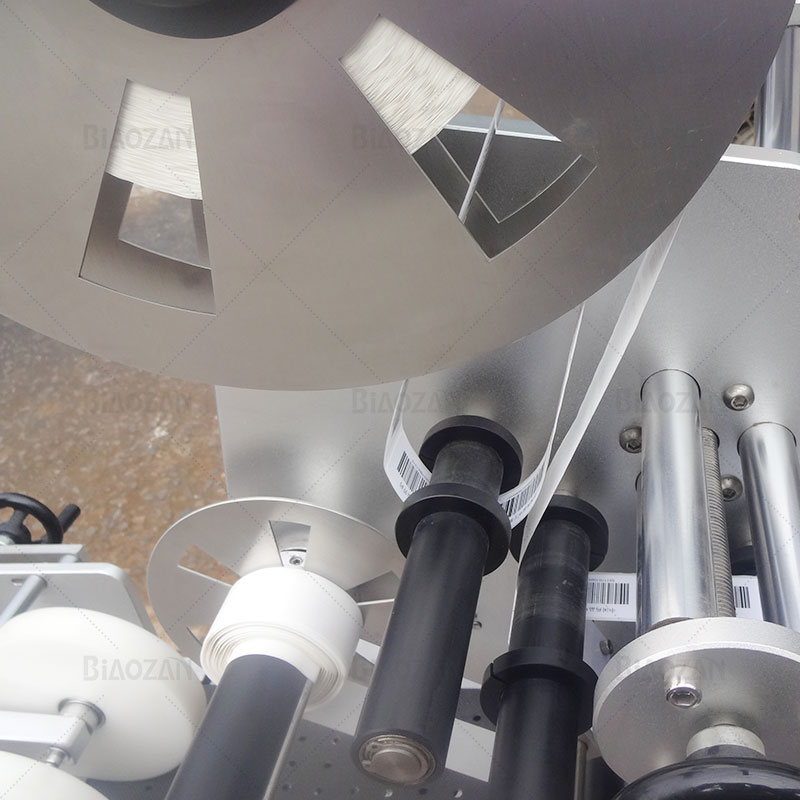

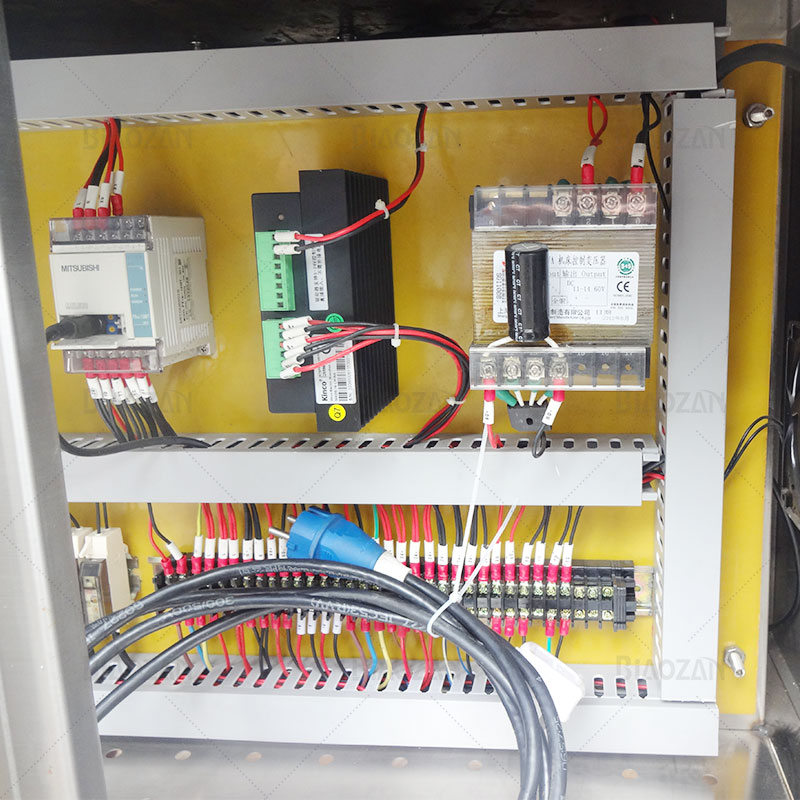

- Adopt mature technology PLC control system, an operation is stable and high-speed.

- Using touch-screen control operating system, simple, practical, efficient.

- Adapt the various shape of the object in top labeling.

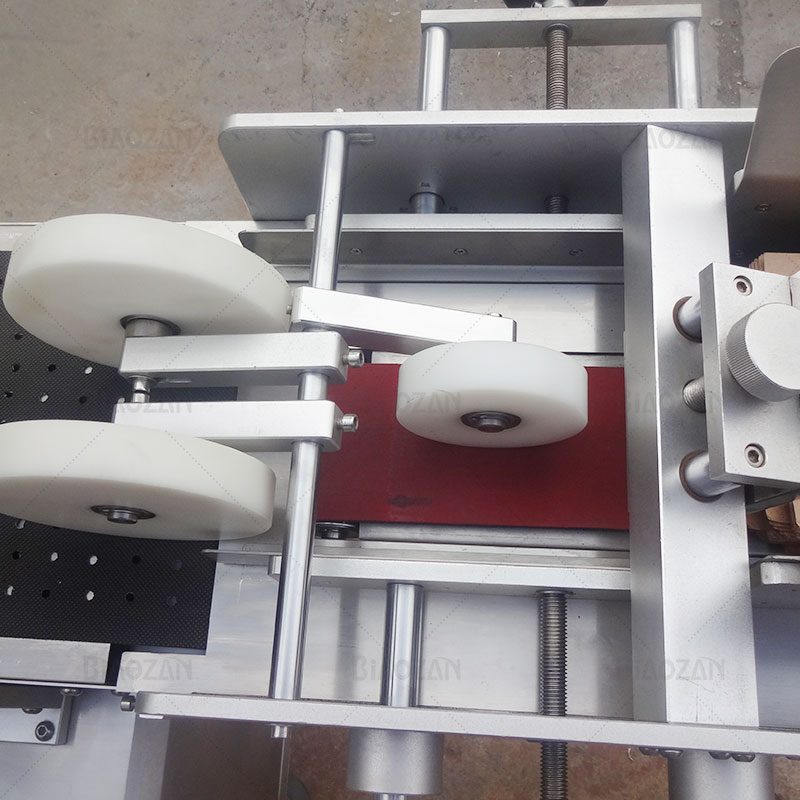

- Screw adjustment to suppress body movements accurately.

- Synchronization chain mechanism ensures labeling smooth and precise calibration.

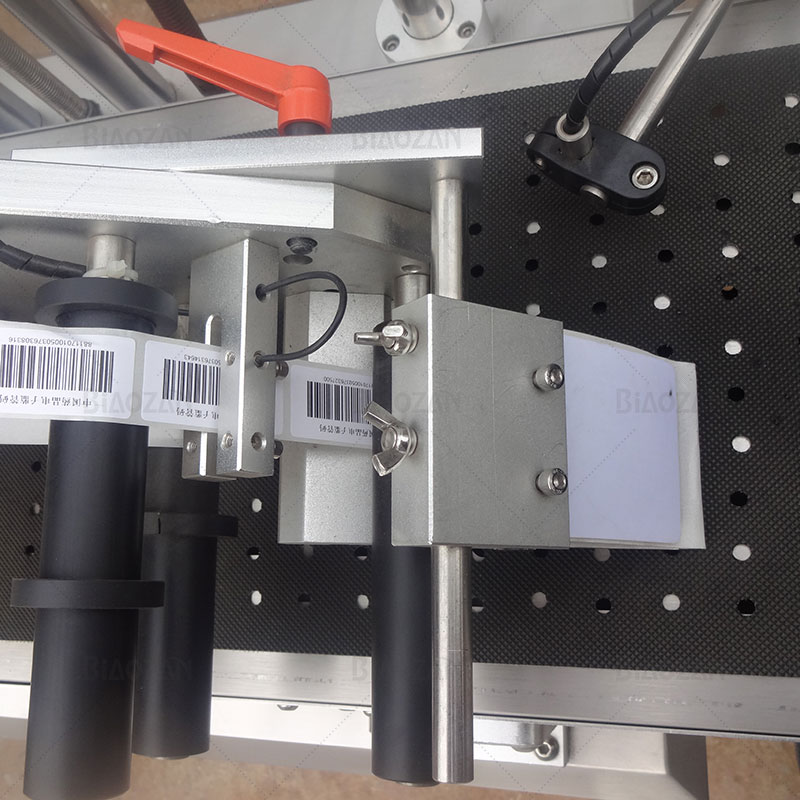

- Advanced technology of pneumatic code system, print batch number and expiry clearly.

- Transmission-type rolling bottles, make sure the labels attached more firmly.

- Labeling transparent label without bubble and wrinkle.

Specifications:

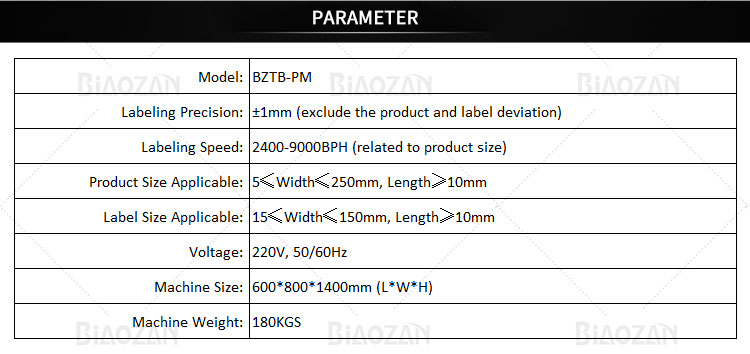

| Model | BZTB-PM |

| Labeling Precision | ±1mm (exclude the product and label deviation) |

| Labeling Speed | 2400-9000BPH (related to product size) |

| Product Size Applicable | 5≤Width≤250mm, Length≥10mm |

| Label Size Applicable | 15≤Width≤150mm, Length≥10mm |

| Voltage | 220V, 50/60Hz |

| Machine Size | 600*800*1400mm (L*W*H) |

| Machine Weight | 180KGS |