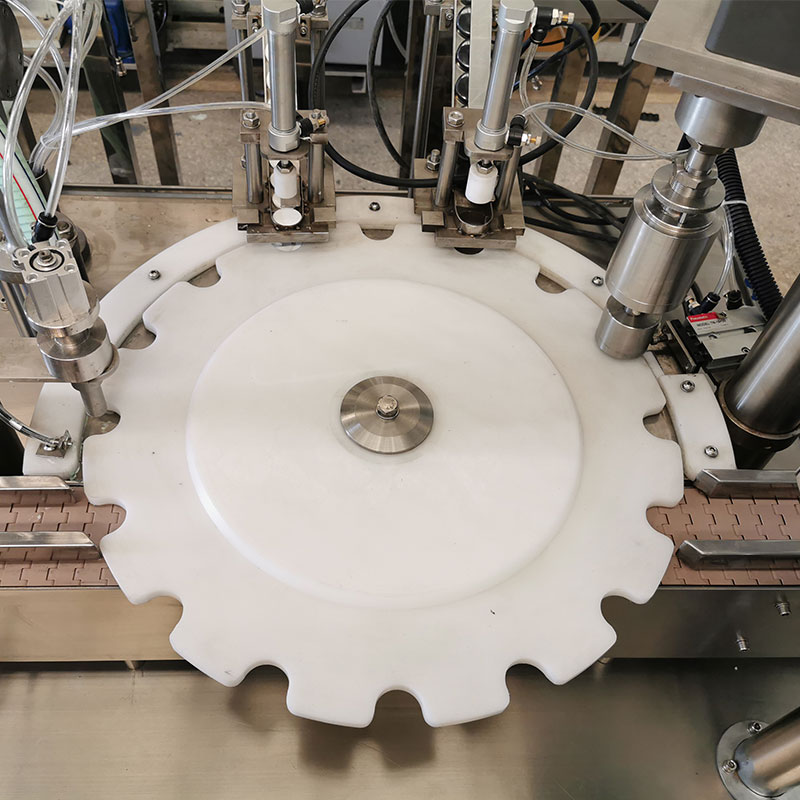

Jar filling capping machine is a new generation utility product, developed from the most advanced technology to suit marketing demands. The machine uses a high-quality SUS304 stainless steel plunger-type metering pump to perform filling, combining automatic filling, automatic cover, mechanical and electrical together. After filling, the machine will put the cap and tighten it with the cylinder. According to different jar sizes, the star wheel should be also changed. The machine is no jar no filling function.

The machine is widely used in the liquid, cream, and paste packaging of pharmaceutical, food, pesticide, chemical, cosmetics, and other industries. Fully meet the requirements of GMP.

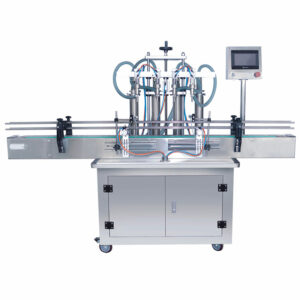

Cream filling capping machine has functions such as automatic screw-type bottle feeding, bottle detecting (no bottle no filling, no bottle no cap feeding ), filling, cap feeding, and capping automatically. This machine can be used in cosmetics, the light industry (daily-use chemical industry), the pharmaceutical industry and food, etc. For those enterprises choosing plastic bottles or glass bottles as packaging containers, this machine can fill the facial cream, grease, emulsifiable paste, gel, or viscous fluids into the bottle for capping and screwing, and finally, output the finished product. The working process can be divided into five main parts: bottle entering the rotary plate, automatic lifting to fill material, automatic capping, servo screwing, and bottle discharging.

Working Process

- Bottle Entering Way: operators put the empty bottles on the turntable, as with the table rotating and the weight of bottles themselves, they will be sent to the conveying belt.

- Bottle Detecting Device: the photoelectric sensor will detect if there is any position lacking the bottle on the turntable, and send the detection signal to the computer to control material filling (has to bottle) or not (no bottle).

- Filling Device: if it’s detected with a bottle in the front station, PLC controls the filling mouth entering the bottle to fill material; if no bottle, there will be no filling.

- Capping Device: arrange the caps automatically through a vibration plate or elevator. With vacuum-taking caps to cap on the bottle, it’s more efficient and stable.

- Servo Screwing: if there is a cap detected, the servo motor will control the twisting force and rotating speed to ensure that the cap is screwed up with the same tightness.

- Bottle Discharge: the well-screwed bottles will be discharged and transmitted to the next procedure.

Features

- Adopt a human-computer interface, the PLC controller, which is easy to operate.

- Use frequency converting control, easy to adjust the filling speed, automatic count.

- Automatic stop, no bottle no filling.

- Round turntable for positioning filling, stable and reliable.

- High precision CAM indexing gage control.

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net