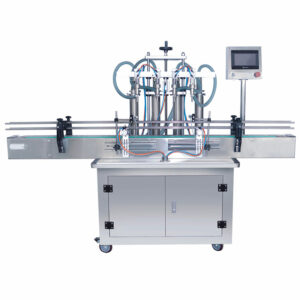

Biaozan’s automatic filling capping machine is used for packaging 30-1000 ML with very good fluidity or slightly viscous liquid, it can not only be used as a single machine, but also can be well combined with a bottle washer, labeling machine, and other packaging equipment to form a packaging line.

We can upgrade the electrical configuration according to customer requirements. Bottle type is PET or glass bottle with plastic screw caps. Different kinds of measuring pumps can be used based on different filling accuracy and liquid characteristics.

Frequency conversion control, arbitrary adjustment of filling, capping speed, automatic counting. Automatic stop function, no filling or no capping without the bottle. Turntable positioning filling, the filling performance is stable and reliable.

Domestic and foreign well-known brands of electrical and pneumatic components, a low failure rate. Automatic liquid level control and feeding.

Optional bottle unscrambler and bottle collector to make the packaging process more automated. Double-clutch capping head with adjustable capping speed and torque. The power of the capping lifting device comes from the turntable, and the capping action is stable.

Specifications:

• Filling Volume: 30-100 ML, 100-500 ML, 500-1000 ML

• Filling Accuracy: ≤ 1%

• Qualified Rate Of Capping: ≥ 99%

• Filling Heads: 2/4/6/8 or customized

• Filling and Capping Speed: 30-50 bottles/min

• Caps Diameter: 10-50 mm

• Other Matching Machines: automatic caps sorting machine, bottle washing machine, bottle unscrambler, automatic capping machine, automatic labeling machine.