HTGF-160 high-speed toothpaste tube filling and sealing machine is a new variety of automatic filling and sealing machines used for filling a specific product (in this case toothpaste) and packaging it in an aluminum tube.

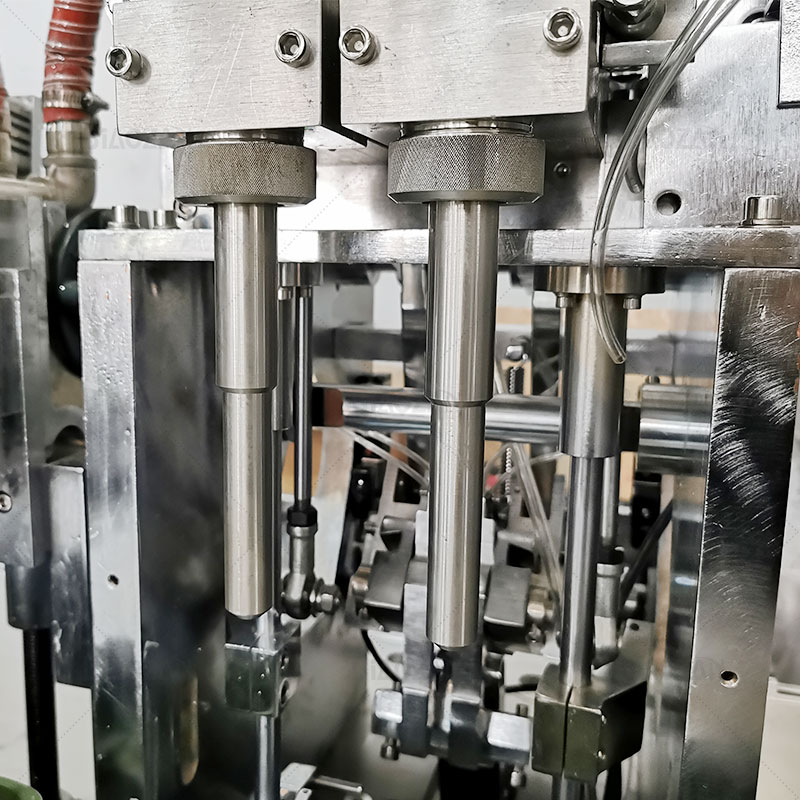

The aluminum tube to be filled is lifted using the automatic lifting device and placed neatly on the large capacity hose loading rack. This rack will neatly arrange tubes in rows both in front and behind. The automatic tube equipment will then rotate the tube 90°. After changing from a horizontal position to a vertical position, the machine will automatically insert the positioning tube seat one by one. The positioning tube seat and inserted tube are rotated with the turntable. When transferred to the filling station, the central cylinder filled with the toothpaste is automatically and accurately injected into the hose at the filling station through the feed swivel directly connected to the cylinder. The rotary disc continues to rotate, folding and pressing the pasted aluminum tube tail, sealing the tail with a three-fold or double fold, and printing batch number. The finished products exit the equipment and are automatically sent to the tube container exterior.

This toothpaste tube filling and sealing machine is capable of operating as a single piece of equipment or be paired with an automatic box loading machine to form a production line. It carries out synchronous production with the box machine using a Cardan shaft and box machine connection.

Technical Parameters:

Suitable Tube Diameter: 22mm-38mm

Suitable Tube Length: 70mm-200mm

Maximum Production Rate: 120 toothpastes/ minute

Motor Power: 3.7KW

Dimension: 3150×1560×2270mm

Weight: 3820 KG

Sealing: tail folding

Power Source: 380V/50Hz

Compressed Air Pressure: 6bar

Cooling Water Pressure: 1.5bar

Color Calibration Precision: 1.5mm

Filling Error: 0.5g

Operation: double pump, tube band

Main Features:

- The frame of aluminum alloy and plexiglass door is fully closed. If any door is opened during normal operations, the machine will automatically stop running and sound an alarm.

- The large capacity dropping box will automatically finish.

- The Siemens PLC controls the frequency. The machine works with a color touch screen, and Chinese or English language selections, allowing users to choose which best suits their needs.

- All parts that come into contact with the toothpaste are made of safe, sanitary stainless steel.

- The tail folding is done in a variety of forms and can be folded either two or three ways.

- The perfect testing system can stop filling when there is no pipe, no filling, or no light. All waste or broken tubes are automatically removed.