Are you in need of a carton packing machine?

If so, then you are reading the right guideline about it.

I have spare time and resources to look into a Cartoning machine or rather, a Cartoner as others may prefer to call it.

To date, a cartooning machine has played a great deal for many businesses when it comes to inventory packaging.

In fact, it has been and still is the commonest form of product packaging.

For instance, food processing, pharmaceuticals, and chemical industries hugely rely on this type of packaging for effective, safer, and secure ways of transporting their products to the market.

And since the market offers a number of Cartoning machines, it is proving to be a daunting task for most people to decide on which Cartoner could be their ultimate choice.

The good news is:

I choose to undertake this initiative to tailor a step-by-step guideline to assist you to reach an informed decision when looking for a Cartoning machine.

This guide is going to teach you all that you need to know about a cartoning machine. It shall cover working principles, classification of Cartoning equipment, and main features to mention but a few.

Our aim is to meticulously elaborate on Cartoning machines, but first, I will begin with a general description of what a Cartoning machine is.

What is a Cartoning Machine?

A cartoning machine is an integration of air, electrical, light, and mechanical high-tech equipment configured to a computer to control, manage and regulate its operation.

The electrical energy is the most essential component of the cartoning machine operation. It is because it powers all the electrical circuit which set in motion all other systems.

For instance, movements of different parts are specifically designed to produce certain desired functions such as circular motion at particular instances form the mechanical part.

In our subsequent chapters of this guide, I will introduce you to main parts of a cartoning machine.

So don’t worry, I will come to all that.

Before that, I want you to watch the video below. It will give you a clear picture of what I am about to discuss in this guide:

I hope you can see how this machine works.

Anyway, let’s come back to our discussion here.

Perhaps the above explanation sounds too technical, anyway you should not worry as we continue, I will break it down into bits and pieces.

This is because it is important to understand better and know everything about Cartoning machines.

Fundamentally, it works by forming cartons.

- It shapes cartons out of blanks to stand up-straight

- Close or/and erect

- Introduce a product

- Folds

- Side-seams and finish by sealing

You could see all of these in the video above. Still, I will explore more of this in this cartoning machine guide.

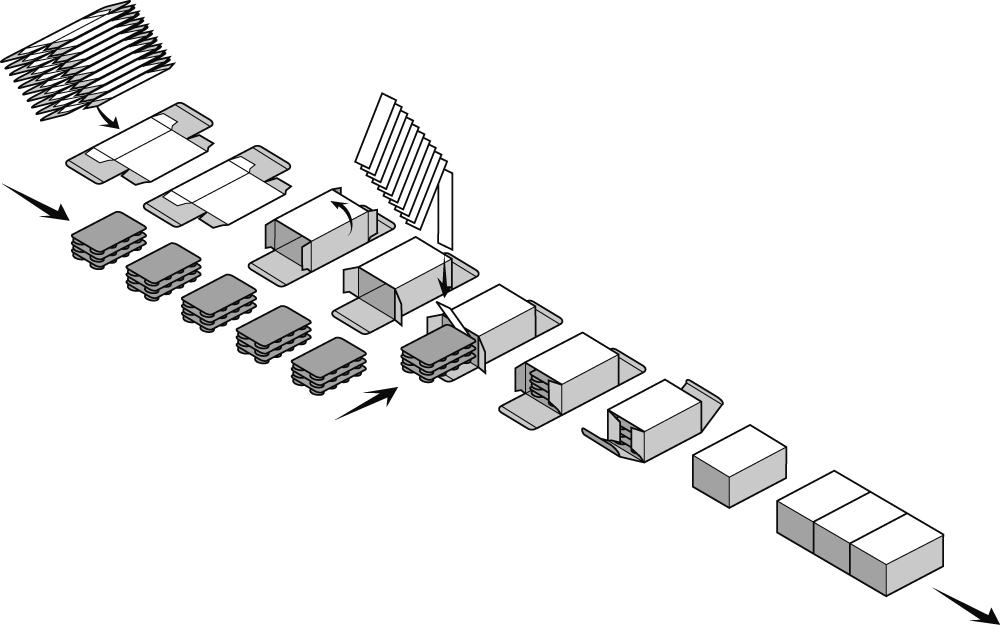

Below is a step-by-step carton-forming process:

What is evident about a Cartoner that makes it different from other packaging machines?

It packages inventory into cartons.

For example, have you ever been to supermarket stores?

You’ll realize that cosmetics or pharmaceutical products are in cartons of different sizes and shapes. Such product packaging is probably done by a Cartoning machine.

That aside:

Another thing that is really intriguing and what you need to consider at any given instance is the:

Carton Shape and Size

Let me explain something here:

I understand that you might still be baffled as to why it is called a cartoning machine yet it is used in product packaging and not carton production.

Well, cartoning machine is simply fed with blank stacks of cartons that are shaped to pack inventory.

So, what are those cartons made up of and where do they come from?

Cartons are made and designed from carton-board: a paper material with semi-flexibility and considerable thickness, used for holding goods especially food or liquids while on transit.

Six-sided rectangular or square shaped cartons are the commonly known cartons, but there are still cartons of various shape and size. These wide range of shapes includes double-wall, octagonal, frame-wall, hinged lids, triangular, tapered trays and wave-shaped.

You must bear in mind that the method deployed in filling and closing determines what shape and size of a carton to be used.

Besides methods of filling and closing the cartons, another significant issue is getting carton to stand up straight to provide clear space for product insertion and sealing it.

Cartons are supplied with different designs to the buyers and some come with pre-cut slots and tabs; others have folds glued with adhesive.

Mostly, cartons are brought in the form of blanks that are flat, cut to shape and size, pre-printed, and others with tabs and slots pre-cut if requested.

Let’s have an overview of the whole cartoning procedure:

Basically, a Cartoning machine is initially fed or rather, supplied with stacks of fold cartons, leaflet or brochures, or production line.

During its operation, the Cartoner picks up a piece, shapes it (or gets it to stand up-straight). It continues to introduce product(s) horizontally or vertically through one open end.

Later in chapter 5, we will look into modes of product insertion handling classification of cartoning machines.

Thereafter, it closes by pushing, folding or turning the flaps of the carton and before applying glue or any other suitable adhesive.

Most Cartoning machines use mechanical sleeve or pressurized air to push products into the cartons. But you should not be surprised when you come across Cartoners that require human input to insert products into the carton.

The above sequence is performed repeatedly forming a chain of packed cartons moving along the guide rail on a conveyor running to carton chute.

Here is another video that illustrates this process:

I trust until this point you have grasped what a cartoning machine is, but for those who have never been to a Cartoning industries, it can sound somewhat strange or tricky.

Before going into why you need cartoning equipment for your business, here is what you must know:

There is a need to understand that different designs of cartoning machines serve different purposes. So, when you order a cartoning machine, make sure it can sufficiently handle your packaging needs.