Filling machines are designed to speed up the production line, especially for liquid bottling operations. Filling systems come in a variety of designs, ranging from semi-automatic tabletop versions to extremely efficient automatic multi-head filling machines.

The size of your operations and the type of liquid you’re working with are among some of the factors that determine the best filling machine for the job. This guide will introduce you to different types of filling machines and help you decide which equipment is right for your business.

What is a Filling Machine?

Liquid filling machines play a vital part in the production of bottled products, including sports drinks and cleaning solutions. Some filling machines can also handle more viscous substances, like pastes, creams, and chunky products such as sauces or salsa.

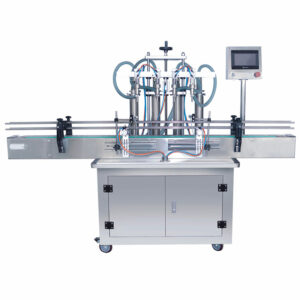

Bottle filling machines are often stainless steel, and range in design from single-head manual filling machines, like a tabletop piston filler, to much more elaborate configurations, like a fully automatic multi-head filling machine with many heads for greater throughput.

Filling equipment must be selected based on key factors, like the desired speed of production, the type of liquid, and the size of the container being used.

How Does a Filling Machine Work?

The purpose of a filling machine is to efficiently deposit a precise amount of liquid into each container based on time, weight, volume, or a combination of these measurements. The exact way in which a filling machine functions depends on a few factors, like whether your production line is semi-automated or fully automated.

With a semi-automated bottle filler, a human typically places each bottle under the machine, but a conveyor belt may assist in this step. A human may also be responsible for deciding when the machine starts and stops releasing liquid into the container.

Fully automated filling machines control the entire process. Typically, a conveyor belt brings clean bottles into the filling area where a sensor identifies them. The machine then starts dispensing liquid before moving the containers to the capping and sealing station. More clean bottles are then moved into the filling area and the process repeats.

Can Biaozan Help Me Customize My Filling Machine?

At Biaozan, we understand that your operation is likely facing unique requirements, and we are happy to offer our engineering expertise to find the right solution for your production line.

We offer a wide range of machinery and we can accommodate foaming liquids, hazardous chemicals, food-grade products, and environments where cross-contamination is unacceptable. If you’re interested in speaking with our team of liquid packing experts, give us a call or visit our website.