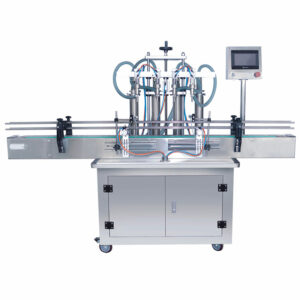

Compact automatic filling capping machines feature an innovative control system on the liquid filling machines providing many different filling options. The bottle filling capping machine is capable of handling many different types of viscous and semi-viscous products.

Distinctive Design

Biaozan’s compact automatic filling capping machine is constructed with S304 stainless steel material, equipped with high-grade SS-316 filling pumps, and incorporated touch screen panel control. The touchscreen interface can adjust most parameters without complicated mechanical adjustment.

Simple to Use

Utilizes our servo-driven volumetric system in single, twin, or quad pump variants. With integrated infeed and outfeed conveyor, product gapping system, and bottle stabilizing clamps to ensure smooth and consistent results. Ideal for use where space is at a premium. Our filling capping machine provides the best filling performance for your products in the market.

FEATURES:

1. Flexibility

- Equipped with high-grade stainless steel 316 filling pumps and partnered with a touch screen panel control, the machine can be easily adjusted by the touch screen interface without complicated mechanical adjustment.

- Constructed of stainless steel and 304 anodized aluminum with full-length product guide rails ensures products remain durable and accurate no matter the size of the product.

- Depending on your needs, this machine has a fill range between 5ml and 1000ml, with 1000ml being the max dosage per filling cycle, subject to cylinder capacity.

- The machine is flexible enough to handle any production schedule and is capable of handling.

2. Productivity

- AC brushless drive-motor system is linked to variable speed control and also featured an emergency stop function.

- The label count feature lets you precisely track progress at any point during the production run.

- Output speed capabilities: 15-120 bottles per minute (subject to filling capacity).

- The machine features a control system with memory slots for storing capping parameters for future operations. This machine encourages productivity by ensuring product parameters are saved to offer product variation. It is easy to switch between products with the settings saved within the machine itself.

- This machine is CE certified and badged giving the assurance of quality equipment.

3. Accuracy

- The machine’s bottle gating system accurately locates bottles under each filling station. This system creates a filling accuracy of +/-0.5%.

- By using servo drive motors during the filling cycle, total control and accuracy are achieved.

Leave your contact information to get a quotation!

[contact-form-7 id=”1836″ title=”联系表单 1″]