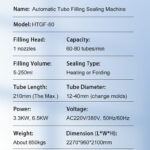

Automatic Tube Filling Machine – HTGF-80 is mechanical-electrical integration, used multiple introduction technology, and is controlled by PLC, it can complete tube feeding, photocell recognition, filling, sealing, date printing, and tube injection automatically simultaneously. The machine runs smoothly, is easy to control, and size changes over, suitable for producing paste products.

This tube filling sealing machine has a modern shape, strong practicability, and good value for the process, it is widely used in toothpaste, ointment, paste food, cosmetics, hair-dyeing, adhesive, art palettes, and so on.

Introdutcion

HTGF-80 tube filling machine adopts a 12 stations design. Suitable for all kinds of folding packing for metal tubes or heating sealing for plastic tubes. Can easily realize the plastic tube and the metal tube packing by replacing the molds and parts. It is the ideal equipment for ALU tubes, plastic tubes, and multiple tube filling and sealing in cosmetic, pharmacy, foodstuff, adhesives, etc industries, and it complies with the standard of GMP. The automatic tube filler and sealer are suitable for filling all kinds of semi-viscous and viscous products into plastic tubes. It can be used for pharmaceuticals, food products, cosmetics, and chemicals. Some of the products filled with this tube filler are ointments, lotions, caulks, adhesives, cheese spreads, and peanut butter.

Working Process

- Plastic Tube: Tube Container → Automatic Tube Loading → Photoelectric Sensor Positioning → Fluid Filling → Tube Hot Melting → Tube Sealing & Date/Batch Number Coding → Tube Checking and Rejecting →Trimming → Output

- Metal Tube: Tube Container → Automatic Tube Loading → Photoelectric Sensor Positioning → Fluid Filling → Folding Tube → Tube Checking and Rejecting → Output

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net