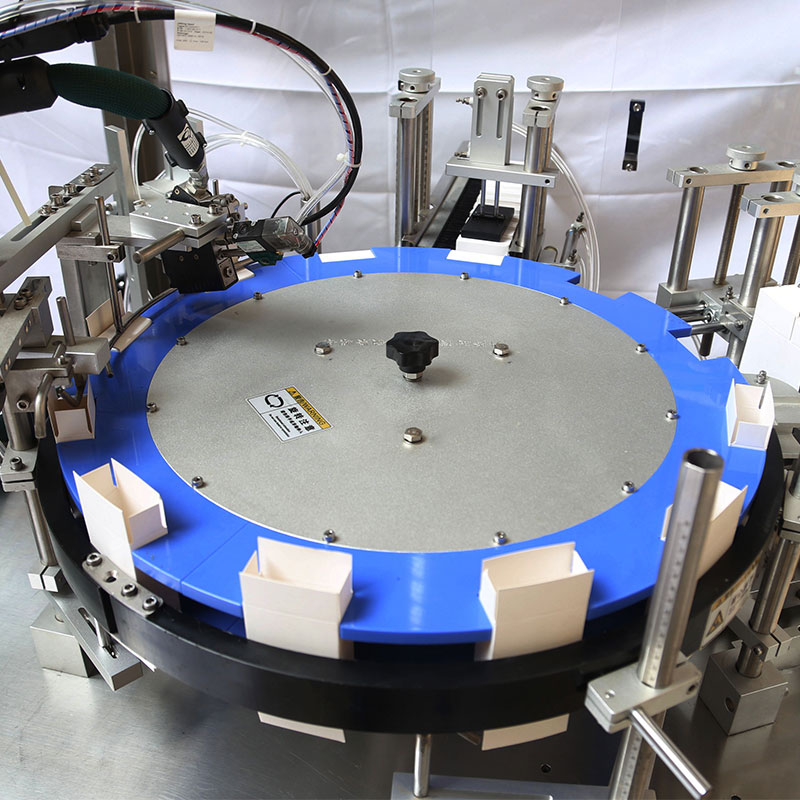

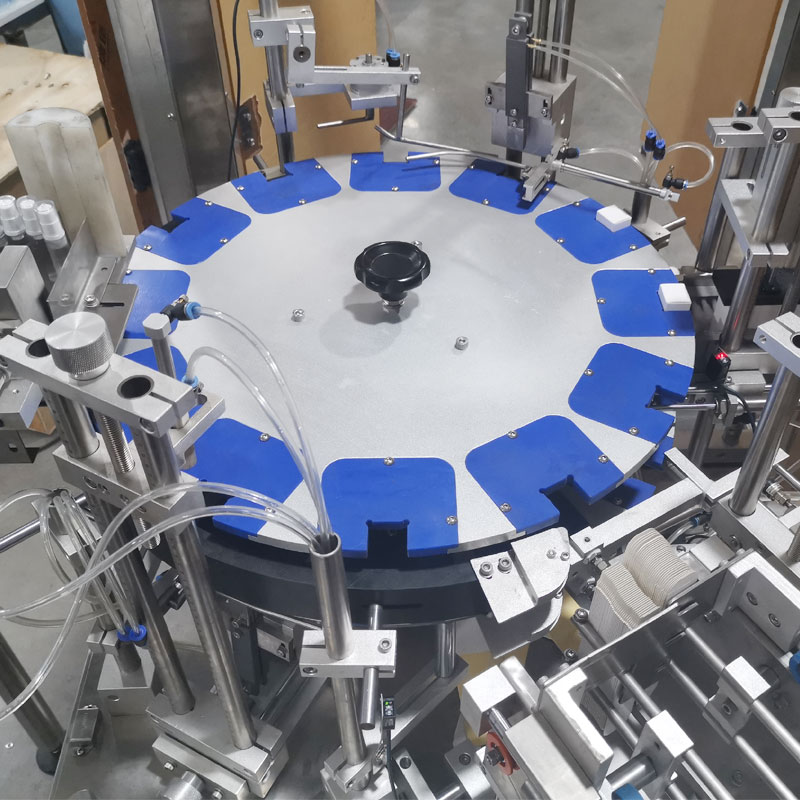

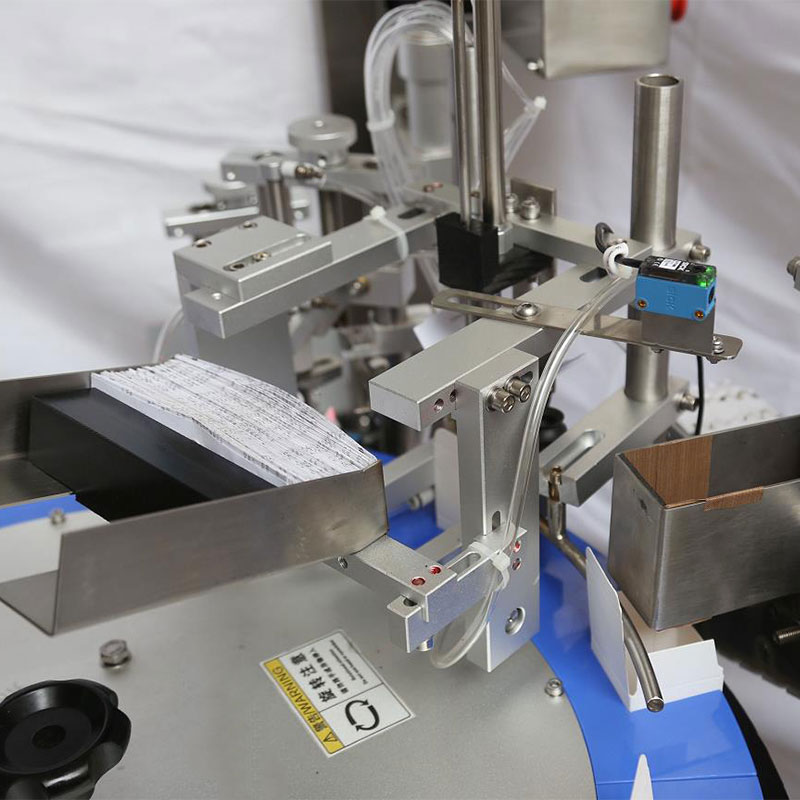

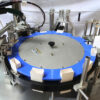

Vertical Cartoning Machine having branded components for electric and pneumatic functions. The simple and steady design confirms the machine’s performance and stability. With various arrangements of feeders, it can auto-feed, Bottles, Vials, Blisters, Tubes, Strips & Pouches to be manually fed. (Leaflet auto-feeding is available.)

This vertical box packing machine is specially designed to pack small quantities of multi-size boxes. With low cost and small floor space. Suitable for all sizes of boxes. It takes a short time to change specifications and change the die. Our vertical box packing machine adopts an advanced PLC control system combined with a 5.7 color touchscreen control panel that can easily set and change packaging parameters. We can also supply a horizontal box packing machine.

The automatic vertical box packing machine is a kind of machine designed by our company on the basis of introducing foreign advanced technology, and it is manufactured strictly according to GMP requirements of the pharmaceutical industry. With high efficiency, high-performance production capacity, manual-folding, and transmission, carton forming, and rear push mechanism-related technology up to European and American standards.

Description

- Installation is quick and easy. Compact size and a patented, centrally located manifold that allows hoses to run right or left means ProBlue melters fit on virtually any packaging line.

- Quick-disconnect power and I/O plugs and a patented,quick-release base design further simplify setup.

- Plus, plug-in modules let you add or subtract hoses and guns to meet changing production needs.

- Daily operation and maintenance are simple. A non-stick, coated tank with three-sided access allows easy, clean filling.

- Graphical controls feature service indicators for maintenance scheduling and status-at-a-glance indicators for ready, fault, and service as well as tank, hose, and gun temperature.

- A disposable filter eliminates the need for routine filter flushing while helping prevent debris and contaminants in the adhesive from reaching your products.

- Operator safety is improved with a patented automatic pressure discharge (APD) valve that relieves pressure into the melter tank in seconds.

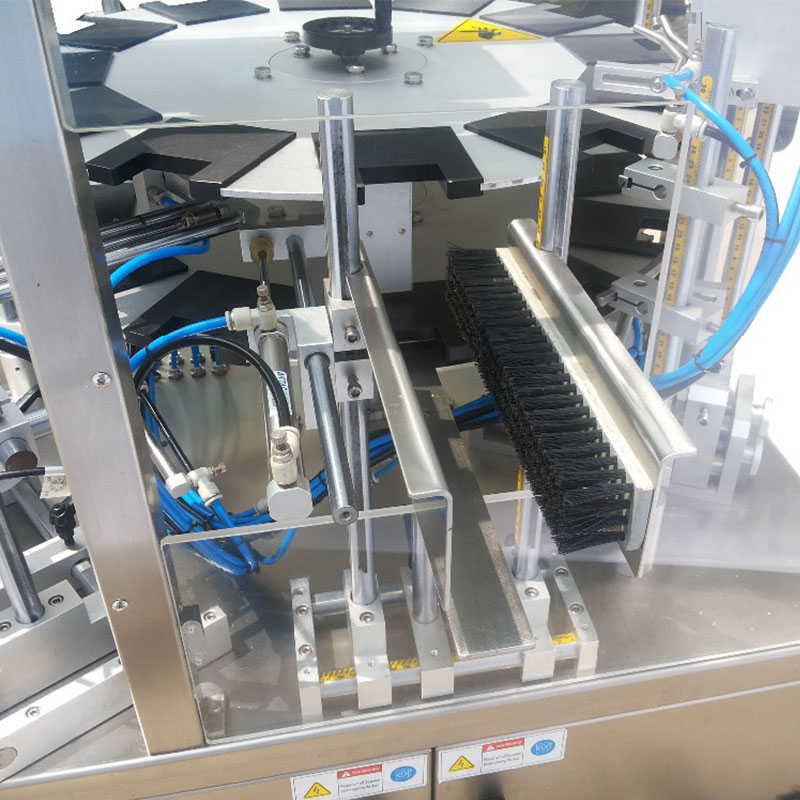

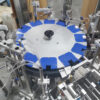

Packing Process

1. Push the box into the star wheel.

2. Fold the box lower small flap.

3. Stamping code on the box.

4. Product falls into the box.

5. Fold the box’s upper small flap.

6. Press both the upper and lower big flaps.

7. Flatten both big flaps.

8. Product push-out.

Leave your contact information to get a quotation!