Why Choice Us:

If you’re in the pharmaceutical, cosmetics, or personal care industry and searching for top-quality tube filling machines, you’ve come to the right place. At [Biaozan], we are a leading Tube Filling Machine Manufacturer, specializing in providing advanced equipment to streamline your production process. Our state-of-the-art tube filling machines ensure precision, efficiency, and exceptional results for a variety of products, including ointments, greases, and more.

Introduction

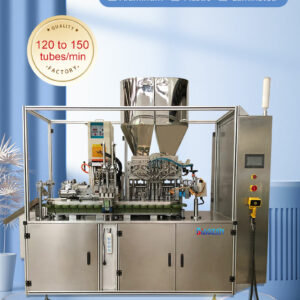

Semi Automatic Tube Filling Machine is mechanical-electrical integration, that used multiple introduction technology and is controlled by PLC, it can complete tube feeding, photocell recognition, filling, sealing, date printing, and tube injection automatically simultaneously. The machine runs smoothly, is easy to control, and size changes over, suitable for producing paste products.

Suitable for

The semi automatic tube filling machine is suitable for filling all kinds of semi-viscous and viscous products into plastic tubes. These tube filler/sealers offer quick adjustment, which makes them suitable for using multiple types of soft plastic and/or metal tubes. This machine features with No−Tube−No−Fill system.

Features

Tube Filling Machine applies the transmission principle. It uses the slot wheel dividing system to drive the conveyor table to do the intermittent movement. with features of stable structure, full function, easy operation, accurate filling, stable running, as well as low noise. It adopts with PLC controller, automatically operating from liquid or high-viscosity material filling till batch number printing. The heating is stable. The sealed tail looks pretty and neat and the trimming is very even. This machine has stable performance and has no noise and pollution during production. We can also supply fully automatic tube filling machines.

Working Process

- Plastic Tube: Manual Insert Tubes → Photoelectric Sensor Positioning → Fluid Filling → Tube Hot Melting → Tube Sealing & Date/Batch Number Coding → Tube Checking and Rejecting →Trimming → Output

- Metal Tube: Manual Insert Tubes → Photoelectric Sensor Positioning → Fluid Filling → Folding Tube → Tube Checking and Rejecting → Output

Get Your Project Started Request a Quotation or Email us at info@bzmachinery.net