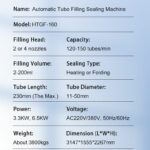

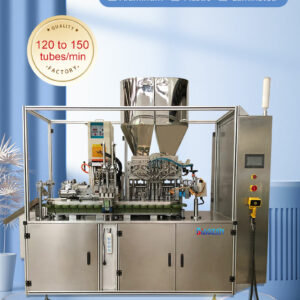

Tube Filling and Sealing Machine – HTGF-160 is our company in reference to foreign advanced tube filling and sealing machine models and combined with the actual situation of the domestic and foreign tubes, independent development, and redesign of a new filling and sealing machine. The smoothness of operation, easy cleaning, easy size changeover, and simple maintenance procedures. These combined with wearing property and the highest safety guarantee makes this an excellent machine.

HTGF-160 high-speed tube filling machine is a high-speed machine, and suitable for filling multi-typed materials as well. For those materials uneasy to fill, for example, food in a large tube, or ointment in a small tube, this machine can provide satisfying quality of filling and sealing tubes.

HTGF-160 is available to handle metal, plastic, aluminum, and laminate tubes. This kind of machine is capable to handle different types of viscous and semi-viscous products like cosmetics, ointment, toothpaste, foodstuff, pharmaceutics, shaving creams, and so on. Control with PLC-based and touchscreen control panel to get world-class performance.

Applicable Industries

Used for the cosmetics industry, light industry (daily-use chemical industry), pharmaceutical industry, food industry, and other industries. The machine is suitable for products that choose tubes as packaging containers. The equipment fills such materials as ointments, creams, gels, or fluids with high viscosity into the tube, then folds and seals the tail of the tube, and prints the word code on the tube to produce the finished product.

Working Process

- Plastic Tube: Tube Container → Automatic Tube Loading → Photoelectric Sensor Positioning → Fluid Filling → Tube Hot Melting → Tube Sealing & Date/Batch Number Coding → Tube Checking and Rejecting →Trimming → Output

- Metal Tube: Tube Container → Automatic Tube Loading → Photoelectric Sensor Positioning → Fluid Filling → Folding Tube → Tube Checking and Rejecting → Output

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net