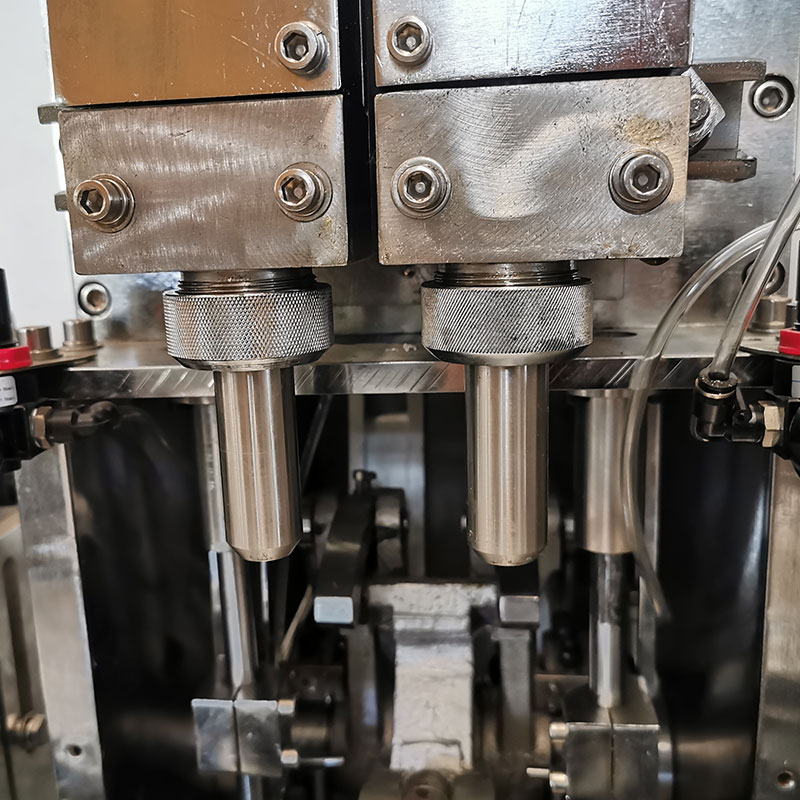

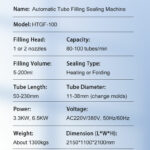

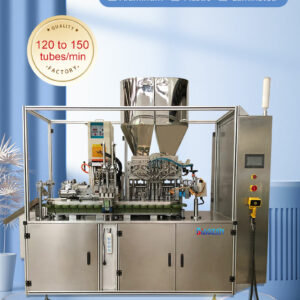

Tube Filling Machine – HTGF-100 using rotary type, double filling heads, high speed. The filling type uses the piston way, and filling accuracy is precision. Filling nozzle anti-drop type, no leak after filling. Easy to adjust the filling volume, and change molds for a different size, and the filling speed can be adjusted. It applies to all kinds of composite tubes, plastic pipe or metal pipe filling and sealing, date printing, cut the tail.

- Soft Tube, Plastic Pipe, Composite Pipe, Metal Tube

- Ointment, Cream, Liquid, Gel Viscosity Fluids Agents.

Applicable Industries

It is widely used in pharmaceutical, cosmetic, food, chemical, and other industries packaging. Such as ointments, gels, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste, and other liquid or paste filling and sealing materials.

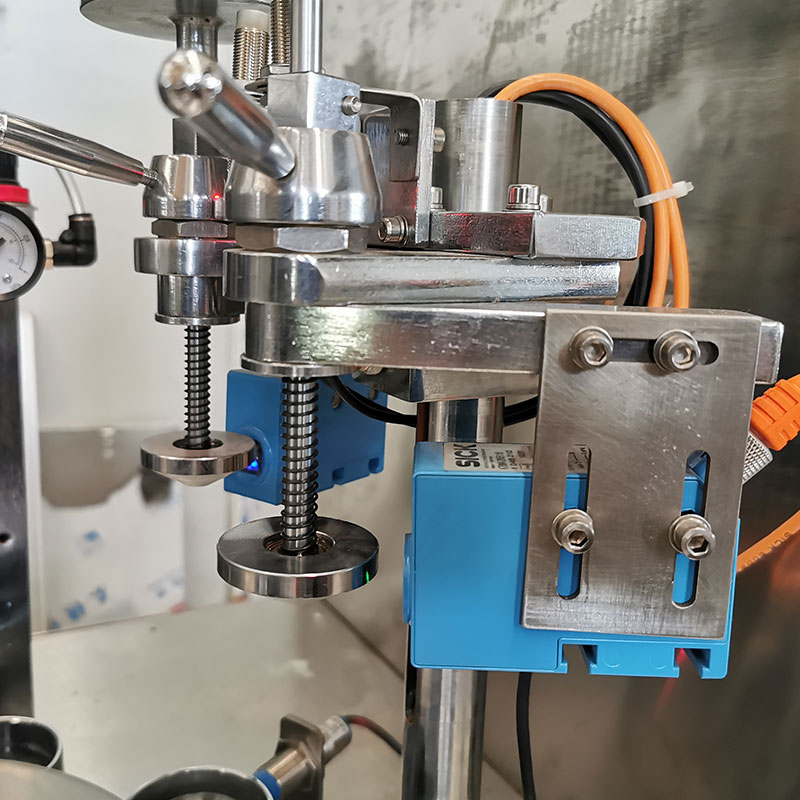

- Plastic Tube: Tube Container → Automatic Tube Loading → Photoelectric Sensor Positioning → Fluid Filling → Tube Hot Melting → Tube Sealing & Date/Batch Number Coding → Tube Checking and Rejecting →Trimming → Output

- Metal Tube: Tube Container → Automatic Tube Loading → Photoelectric Sensor Positioning → Fluid Filling → Folding Tube → Tube Checking and Rejecting → Output

Get Your Project Started Request a Quotation or Email us at sales@bzmachinery.net